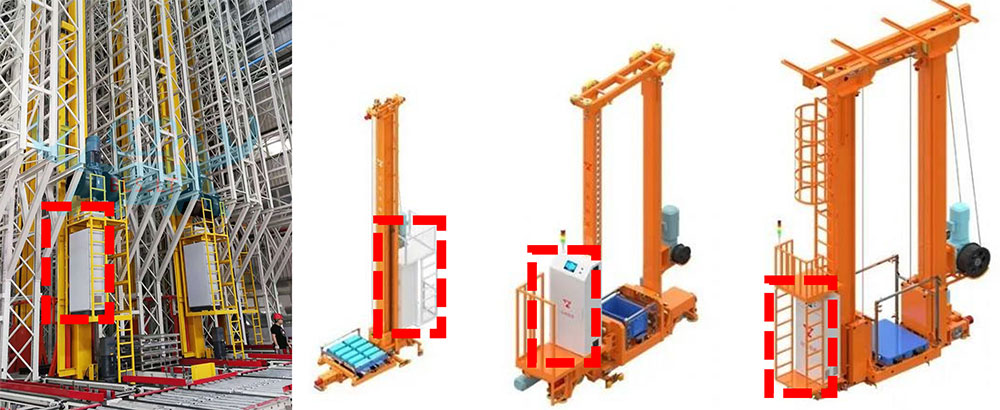

SERVO STACKER CRANE AUTOMATIC STORAGE AND RETRIEVAL SYSTEM

A servo stacker crane is an important logistics node in modern logistics systems and its application in logistics centers is becoming increasingly widespread. Currently, the tallest servo stacker cranes in the world can reach a height of 50 meters. The storage capacity per unit area of a servo stacker crane can reach 7.5 (t/m²), which is 5-10 times that of a regular warehouse. By utilizing high-level shelving for storing goods, the storage area can be developed vertically, making full use of warehouse floor and space. As a result, it saves inventory floor space and improves space utilization. By using machinery and automated equipment, the operational processing speed is increased, thereby enhancing labor productivity and reducing the labor intensity of operators.

S1500 servo three-dimensional warehouse

We provides manufacturing, circulation and distribution companies with intelligent warehouse automation and logistics system planning and design, system integration, software development, equipment customization, electronic control system development, on-site installation and debugging, customer training and after-sales service, etc. to help customers achieve material entry and exit. Automation, informatization and intelligence (development and integration of WMS and WCS systems) of warehouse, storage, transportation, picking, distribution and other processes to improve efficiency, reduce costs and create value for customers.

- 2 months

Delivery time

- ↓ 40%

Delivery time

- ↑ 20%

Increased storage

-

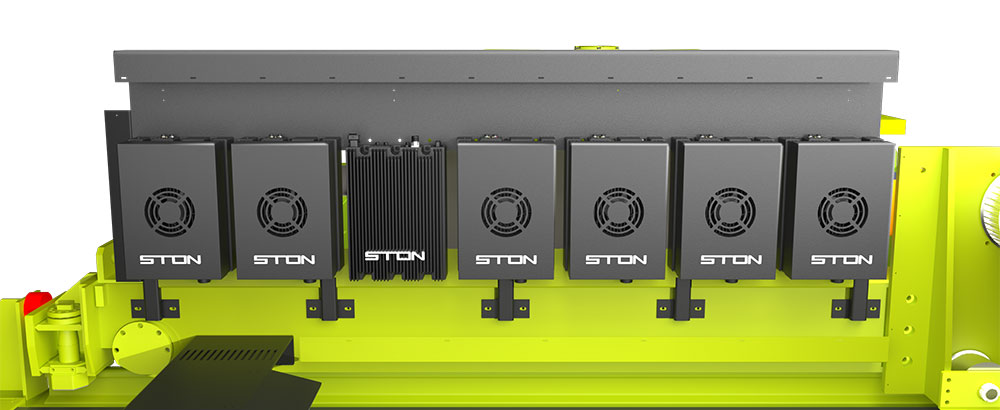

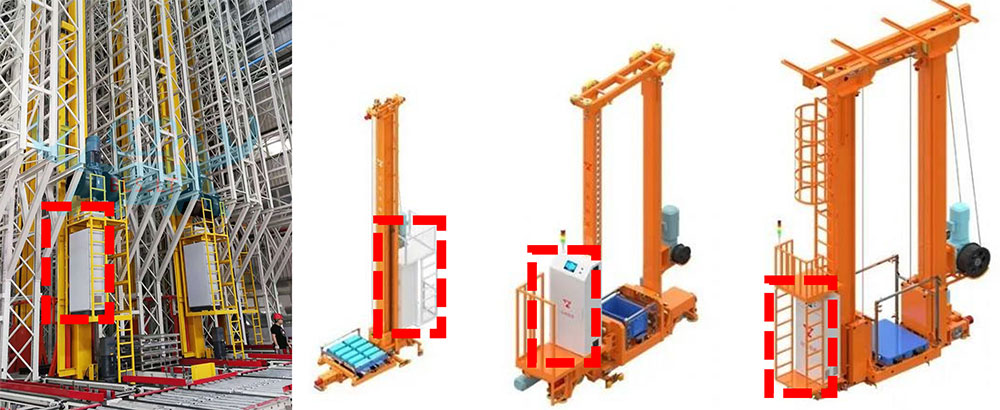

Cabinetless Control System®

Cabinetless Control System®Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

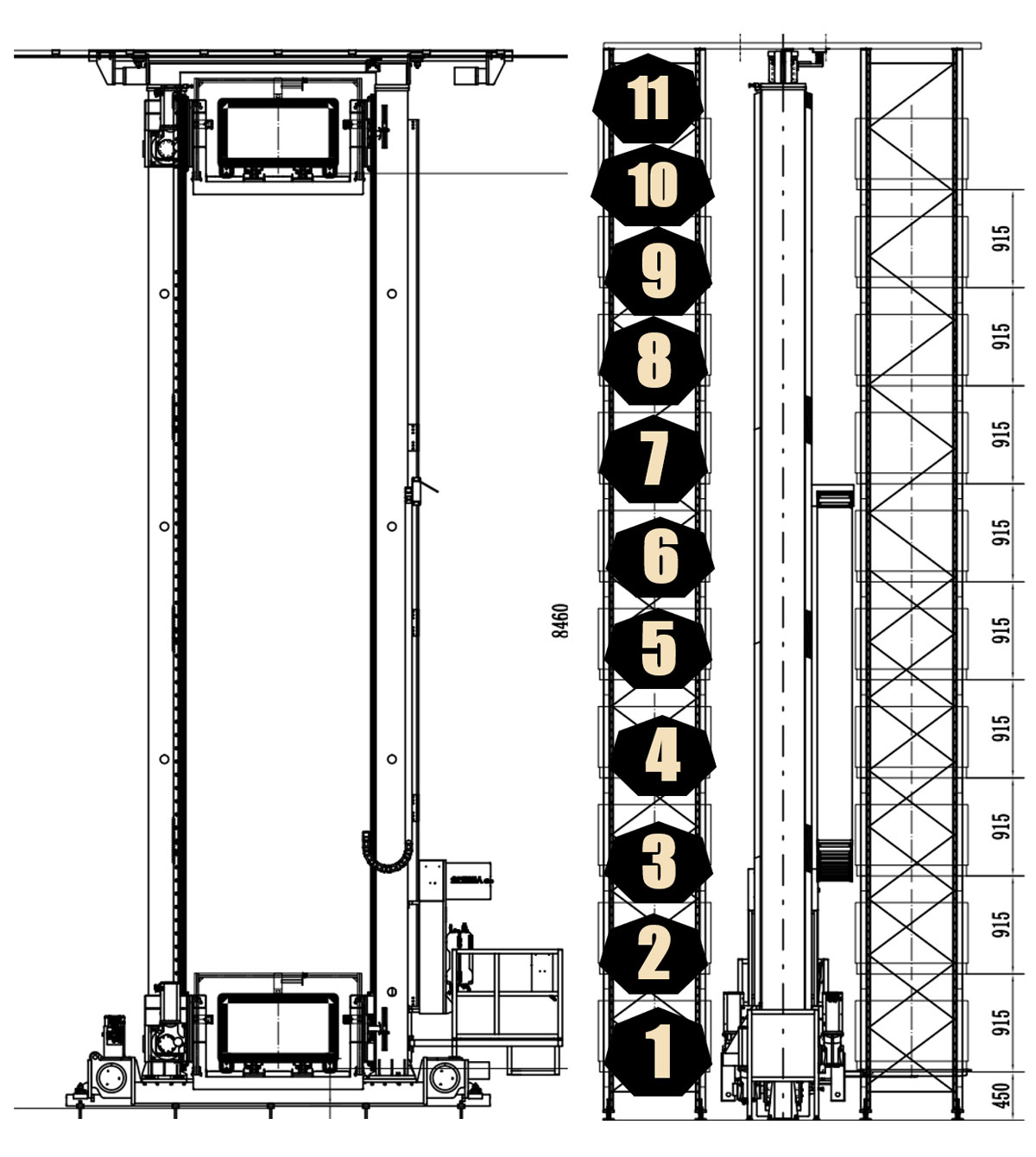

20% more storage capacity than traditional stacker cranes

20% more storage capacity than traditional stacker cranesThe traditional stacker has 9 layers and the STON stacker has 11 layers, increasing the storage capacity by 20%. The drive uses gears, racks, and servo motors without wire ropes.

-

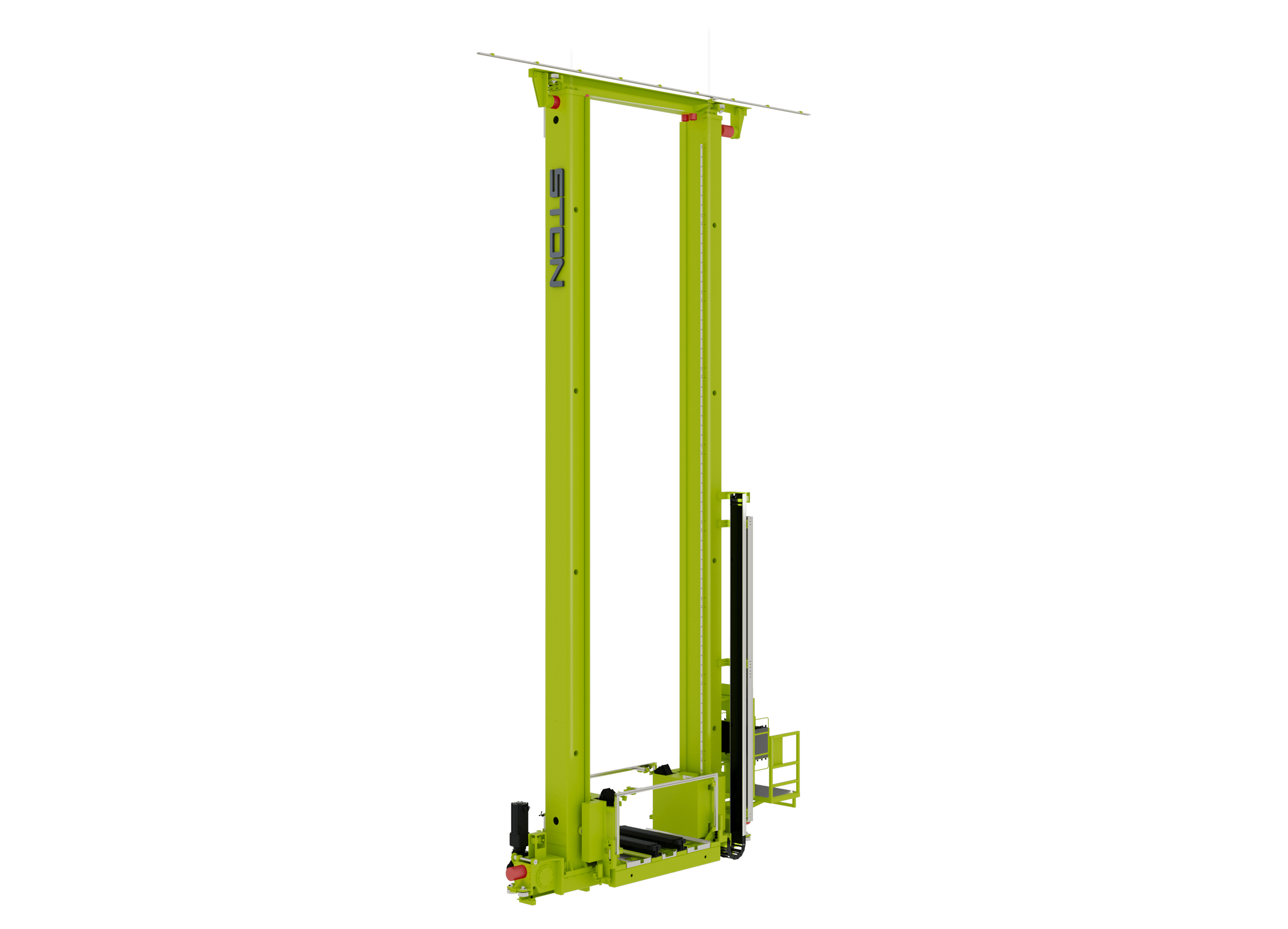

Ultra-high factory building with heavy load

Ultra-high factory building with heavy loadUp to 40 meters, maximum load 10 tons

-

Wide range of applications

Wide range of applicationsSuitable for light, small volume and rapid sorting of multiple types of goods

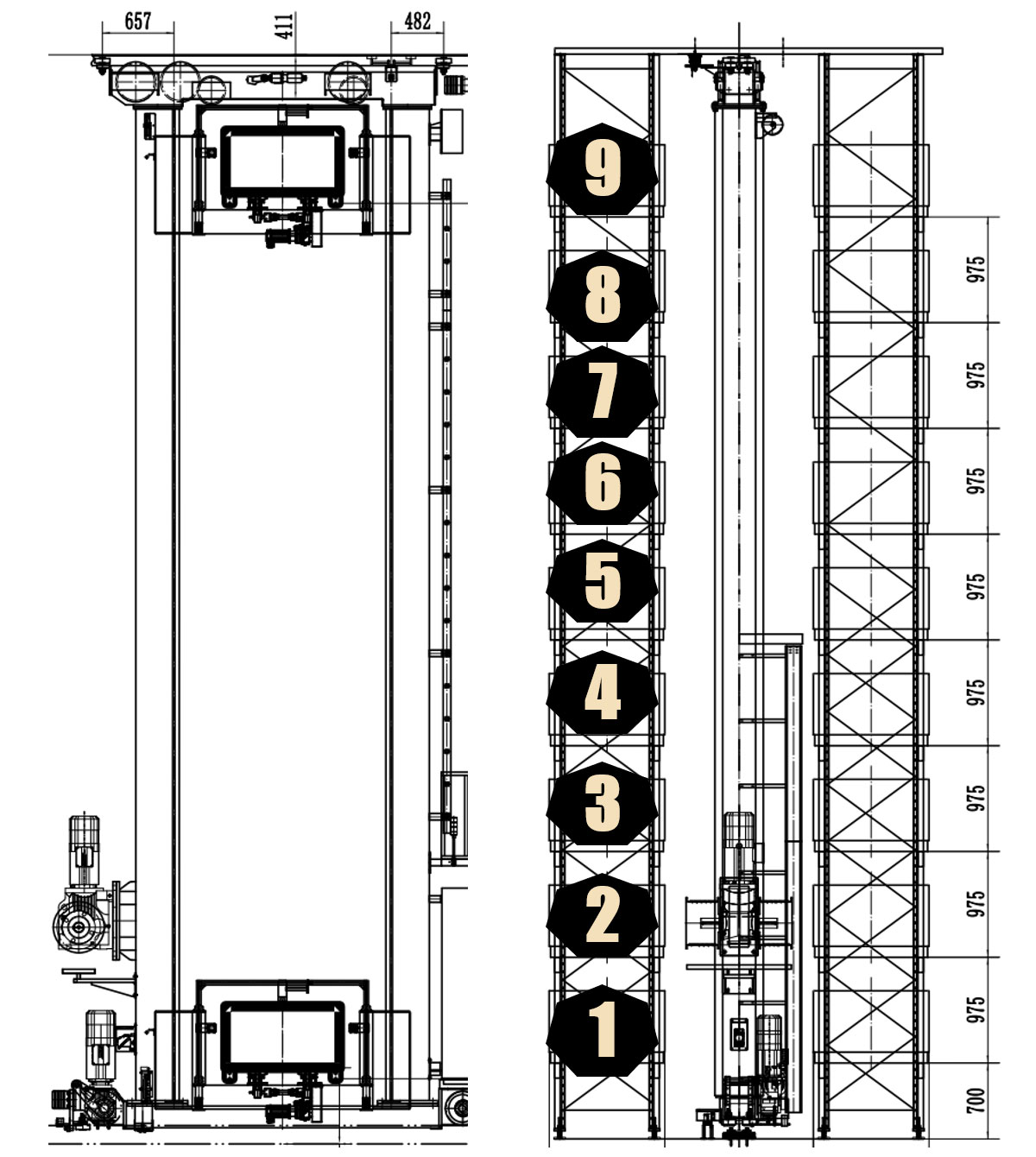

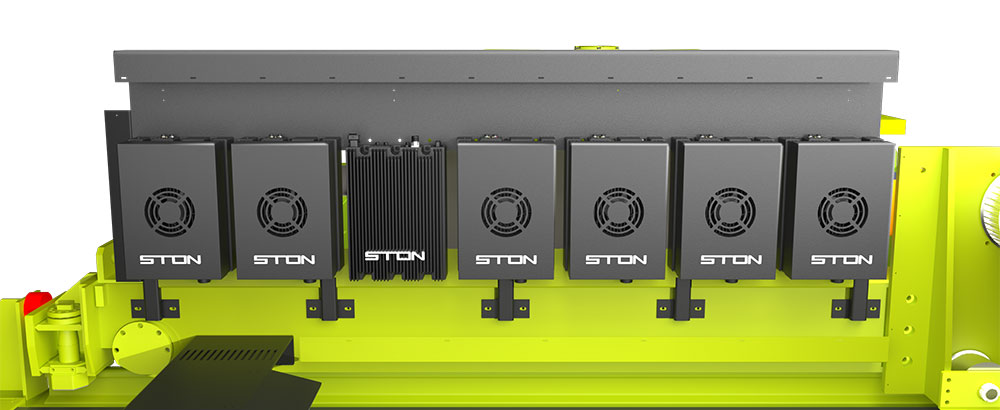

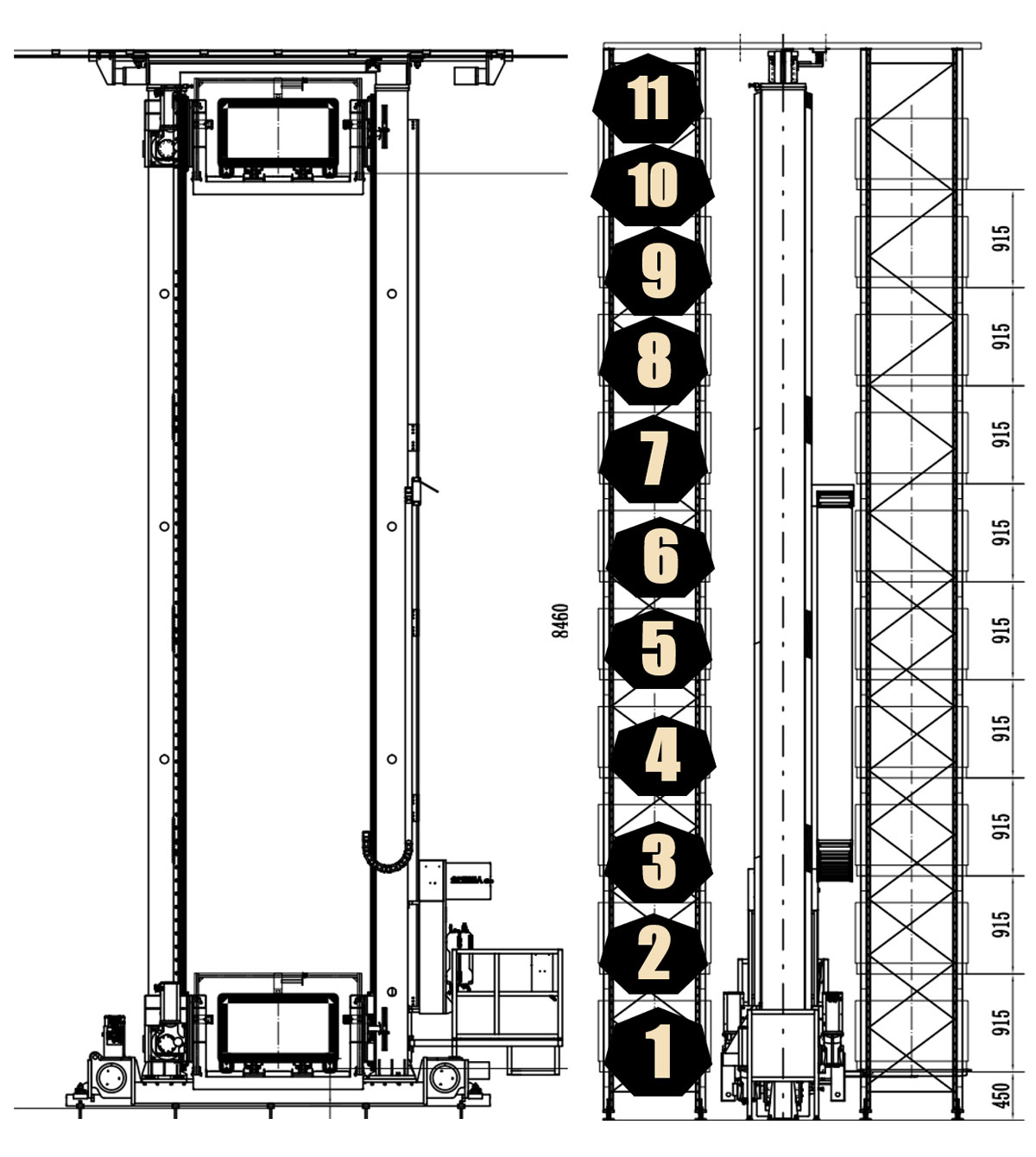

- STON stacker 11th floor

The traditional stacker has 9 layers and the STON stacker has 11 layers, increasing the storage capacity by 20%. Servo dual drive, high gear positioning accuracy and strong structural rigidity.

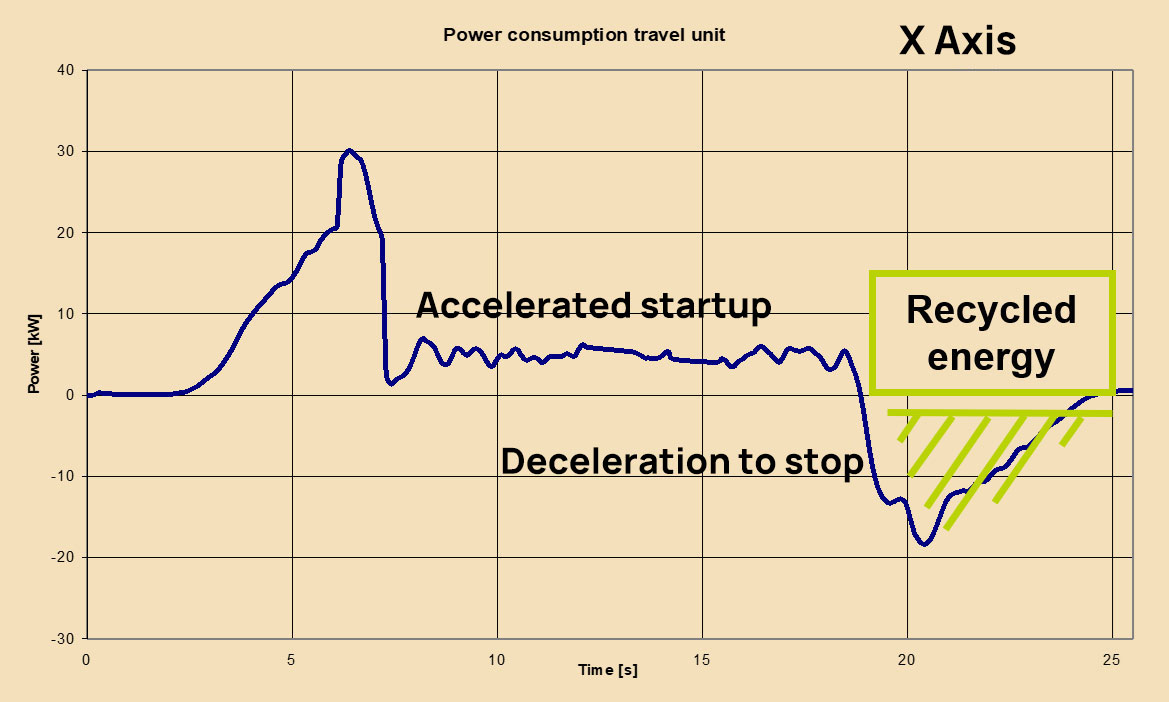

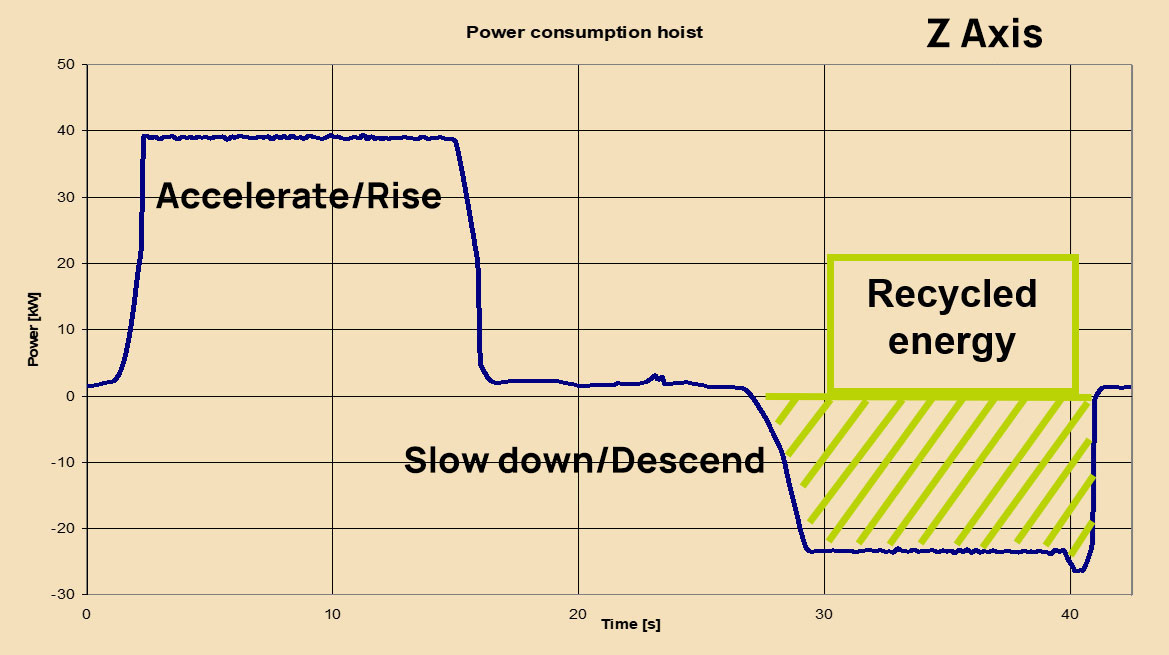

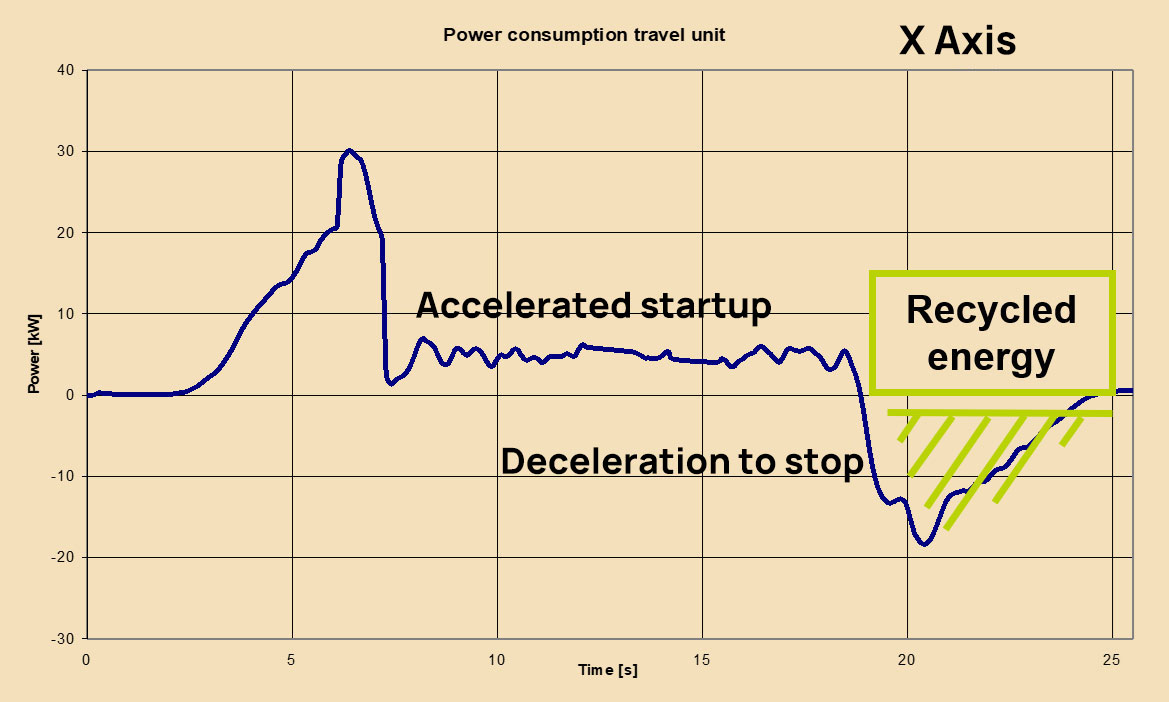

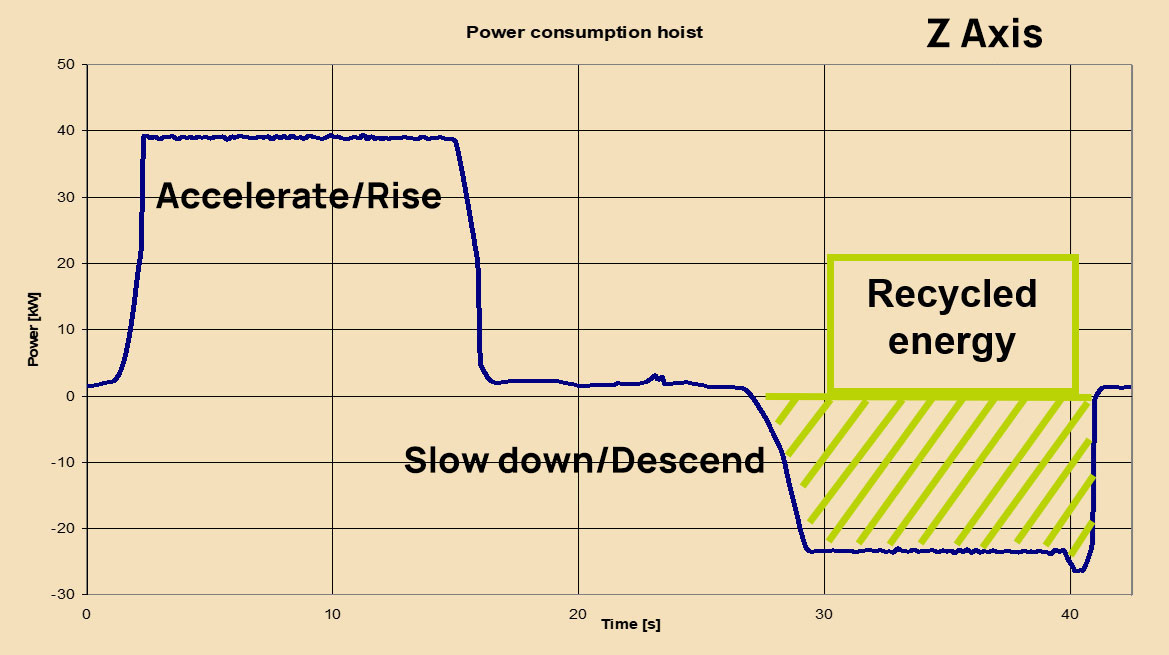

- DC common bus power regeneration technology

Gigabit ring network and male bus technology save 40% energy.

- Drive and control integrated

The control system does not require electrical debugging, perfectly solving the problem of 2-month delivery time.

| Load | 50-1000kg |

|---|---|

| High | 3-40m |

| Horizontal speed | 3-200m/min |

| Boost speed | 3-60m/min |

| Fork speed | 3-45m/min |

Servo dual drive & drive control integrated Three-dimensional warehouse that can be delivered in 2 months

-

In a traditional three-dimensional warehouse, 4 to 5 months are spent on manual debugging and programming.

Stacker control is still monopolized by Siemens, but in recent years due to Siemens price and delivery issues there is an urgent need for alternatives! -

-

Compared with traditional three-dimensional warehouses, which require 6 to 10 months of delivery, ours only takes 2 months at the fastest.

Servo dual drive & precise positioning New stacker system without wire ropes

increases storage capacity by 20%

increases storage capacity by 20%

- Traditional stacker crane 9 layers

-

- Servo stacker 11 layers

Standard power recovery system Energy saving up to 40%

-

- DC common bus power regeneration technology

Gigabit ring network and male bus technologyUsing independent Gigabit industrial bus technology Glink-II , the data exchange rate reaches millisecond level. Due to the fast data exchange speed, the overall line efficiency is more than 30% faster than the traditional control method, and the safety and reliability are also doubled.

Gigabit ring network and male bus technologyUsing independent Gigabit industrial bus technology Glink-II , the data exchange rate reaches millisecond level. Due to the fast data exchange speed, the overall line efficiency is more than 30% faster than the traditional control method, and the safety and reliability are also doubled.